How Do Inventory Labels Aid Stock Management?

In the fast-paced world of inventory management, staying organized is key. Whether you’re managing a small retail store or a large warehouse, having an efficient system for tracking and managing stock is crucial.

That’s where inventory labels come into play. These small but essential tools help businesses maintain order, reduce errors, and improve overall efficiency. In this blog, we’ll look at how inventory labels aid stock management and why they’re essential for any business looking to optimize its operations.

What Are Inventory Labels?

Before getting into the benefits, let’s start with the basics: what exactly are inventory labels?

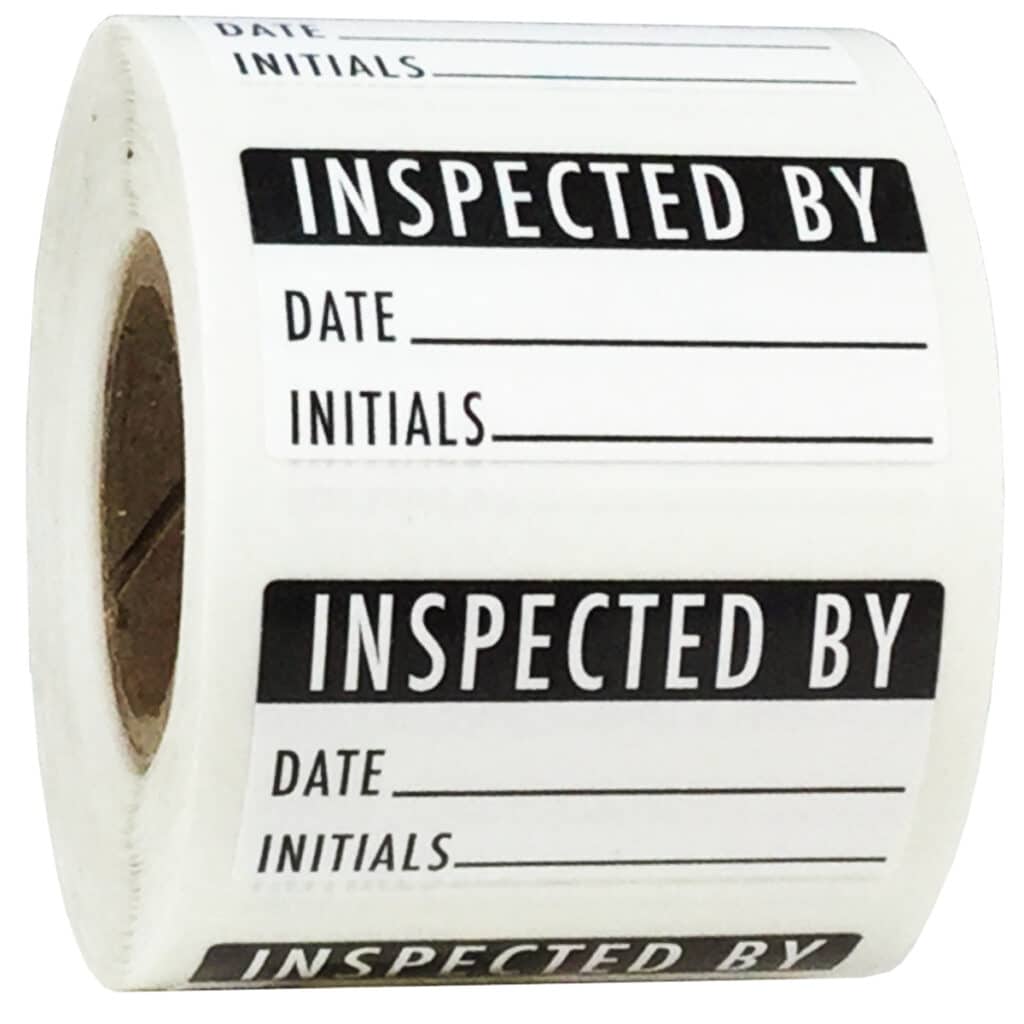

Inventory labels are tags or stickers used to identify and categorize items within a stock management system. They typically include information such as product codes, descriptions, and barcodes.

Depending on the complexity of the inventory system, these labels can also contain additional data like expiration dates, batch numbers, or location codes. The main purpose of inventory labels is to provide quick, easy access to product information, streamlining the processes of tracking, organizing, and managing stock.

The Role of Inventory Labels in Stock Management

Inventory labels are crucial in several key areas of stock management. Let’s break down how they contribute to more efficient and accurate inventory control.

Streamlining Organization

One of the primary functions of inventory labels is to help organize stock. By clearly labeling each item or group of items, businesses can easily categorize their products, making it simpler to locate them when needed. This is particularly beneficial in large warehouses or retail environments where products can easily become misplaced or mixed up.

- Clear Identification: Labels make it easy to identify items at a glance, reducing the time spent searching for specific products. This is especially useful during busy periods when quick retrieval is essential.

- Categorization: With the help of inventory labels, items can be grouped and organized by category, size, color, or any other relevant criteria. This not only helps in maintaining a neat and orderly stockroom but also makes restocking and inventory checks more efficient.

Improving Inventory Accuracy

Accuracy is a major component of effective stock management, and inventory labels play a significant role in achieving it. Errors in inventory can lead to stockouts, overstocking, and ultimately, lost sales and wasted resources.

- Reduced Errors: By providing clear information on each product, inventory labels help reduce the risk of human error. Employees are less likely to pick the wrong item when the label provides all the necessary details at a glance.

- Efficient Stock Counts: Labels with barcodes or QR codes can be scanned during stock counts, making the process faster and more accurate. This reduces the reliance on manual entry and helps maintain up-to-date inventory records.

Enhancing Tracking and Tracing

Keeping track of inventory is a critical part of stock management. Inventory labels facilitate this by allowing businesses to monitor stock levels, track item locations, and trace products through the supply chain.

- Real-Time Tracking: With barcodes or QR codes, inventory labels enable real-time tracking of stock movements. This means businesses can instantly see where an item is located, whether it’s on the shelf, in transit, or out for delivery.

- Batch and Lot Tracking: For industries like food and pharmaceuticals, it’s crucial to track items by batch or lot number. Inventory labels provide this capability, helping businesses maintain compliance with regulations and quickly address any issues related to product recalls or quality control.

Supporting Efficient Reordering

Effective stock management isn’t just about keeping track of what you have; it’s also about knowing when to reorder. Inventory labels can assist in this area by providing key information that supports the reordering process.

- Reorder Alerts: Labels can include information about reorder points, making it easier for employees to know when it’s time to restock. This helps prevent stockouts and ensures that popular items are always available.

- Supplier Information: Including supplier details on inventory labels can streamline the reordering process. Employees can quickly see which supplier to contact for each product, saving time and reducing the chance of errors.

The Importance of Customization

Every business is unique, and so are its inventory management needs. Custom inventory labels allow businesses to tailor their labeling system to suit their specific requirements.

- Industry-Specific Needs: Different industries have different labeling needs. For example, a food distributor might need labels that indicate expiration dates, while a clothing retailer might need labels that specify size and color. Custom labels can be designed to meet these specific needs.

- Branding Opportunities: Custom labels aren’t just functional—they can also be a branding tool. By incorporating a company logo or color scheme, businesses can reinforce their brand identity while keeping their inventory organized.

Getting Started with Inventory Labels

If you’re looking to improve your stock management with inventory labels, here are some steps to get started:

- Assess Your Needs: Determine what information needs to be included on your labels based on your inventory management system and industry requirements.

- Choose the Right Labels: Select labels that are durable and suitable for your environment, whether that’s a cold storage facility, a high-traffic warehouse, or a retail store.

- Implement a Scanning System: If you’re using barcodes or QR codes, ensure you have the right equipment and software to scan and track your inventory effectively.

- Train Your Team: Make sure your employees are familiar with the labeling system and understand how to use it to maintain accurate inventory records.

Conclusion: The Power of Inventory Labels in Stock Management

Inventory labels are an essential tool for effective stock management. They help businesses stay organized, reduce errors, track inventory accurately, and support efficient reordering.

By investing in a robust labeling system, you can streamline your operations, improve accuracy, and ultimately, enhance your bottom line. If you’re ready to take your stock management to the next level, check out our range of inventory labels and see how we can help you stay on top of your inventory.